|

The creators of Clear Penetrating Epoxy Sealer Easy 1:1 Mix - No Blush Epoxy |

|

The creators of Clear Penetrating Epoxy Sealer Easy 1:1 Mix - No Blush Epoxy |

|

Weather is brutal to wood and paint. Many historic homes have sound wood siding but will not hold paint. Over the years bacteria and fungus has made the surface of the wood spongy. Paint particles are not small enough to get through to sound wood. Soon after painting, the bacterium has eaten enough of the wood to render it unable to hold paint. The paint peels off the wood. If left in the weather long enough water will transport the bacteria deep into the wood and create dry rot. End grain is nothing more than a sponge to hold the moisture and accelerate dry rot. This never-ending cycle is why Clear Penetrating Epoxy Sealer was invented. Unlike an adhesive epoxy, CPES; is water thin epoxy made for penetrating, which soaks far into damaged wood. The solvent base is the transport mechanism to deliver the epoxy resin into the open spaces within the wood. The same solvents also evaporate excess moisture from within the wood. All of the wood fibers and spores are then left encapsulated with the remaining epoxy. It glues the remaining fibers back together, and restores useful strength back into the wood, without changing the natural flexibility of the wood. Cold weather formula of CPES will cure below freezing for winter use. Natural Wood Appearance may be attained by using Epoxy Clean Up Solvent. CPES is the only product that evaporates excess moisture from within the wood! Unlike adhesive epoxy products CPES does not put a rock in the wood! Imagine a bundle of straws with one end dipped in paint and removed. Like the cell walls of the wood, the straws are coated but air will still flow through their centers. CPES treated wood will allow molecules of air and water to enter the wood allowing the wood to expand and contract with changes in temperature and humidity. CPES is derived from natural wood resins and so develops a chemical adhesive bond to the wood fibers themselves. Other types of products do not work because they do not expand and contract with the wood like CPES; does. Since they do not penetrate into the wood fibers, the bacterium takes over, freeze-thaw loosens the bond and in a short time the decay takes over. |

||

|

|

||

|

|

| ||

|

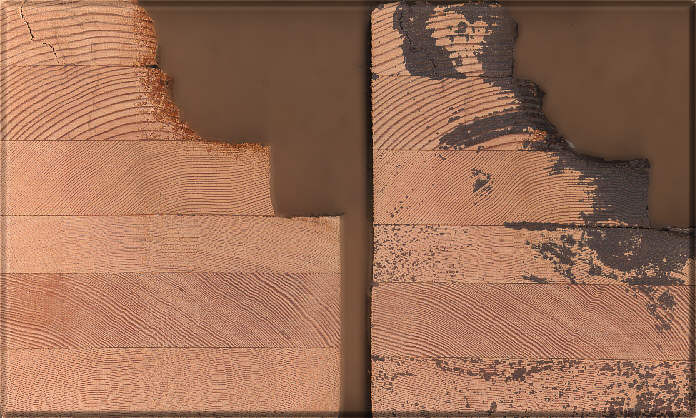

These two laminated beam sections were adjacent slices, cut

side-by-side and one treated, so you could compare the almost-identical

wood before and after impregnation. The fungi that cause rot leave

an abnormal porosity in apparently-sound wood near the decay.

This is why rot starts up again behind conventional repairs with other products. The slice on the right was treated with Clear Penetrating Epoxy Sealer™ [CPES™] dyed blue, so that regions of abnormal porosity would be visible after impregnation. |

The wood was placed in a shallow tray and the liquid wicked up into the wood. In only a few minutes, in regions where the fungi had eaten the wood, the dyed resin was now visible. CPES Impregnating Resin impregnates deteriorated wood much more than sound wood, because it has more porosity. These regions are now impregnated with a highly rot-resistant and water-repellent resin, and useful mechanical properties are restored. This treatment improves the ability of the wood to resist further deterioration. This is the first step in the restoration process. When finally painted, the impregnating resin glues the paint to the wood, so it sticks better and lasts longer. |

|

|

Wood is the primary material CPES; is designed for. Plywood will not check when painted. Exposed end grain will not rot. Painting over uncured CPES; will molecularly glue the paint, primer or varnish to the wood. Natural weathered wood appearance can be maintained after treatment by wiping the surface with a rag carrying clean up solvent. Any other materials that absorb water will benefit from CPES; too. Old crumbly mortar can be consolidated; porous tile can be sealed without sheen, and CPES; will prevent freeze-thaw damage to concrete. CPES is available in both Warm and Cold weather formulas. The long working time (pot life) of these products mean they will retain their penetrating and moisture-dissolving ability for more time. Cold Weather Formula allows restoration to be completed sooner and be done in cold temperatures. Nighttime temperatures are usually much less than than daytime temperatures and so provides less progress towards full cure than day. This makes the Cold Weather Formula valuable when the daytime temperatures are in the 50°F~60°F range and/or night temperatures are in the 30°F ~40°F range. Use the following table as a temperature guideline: |

|

Warm Weather Formula |

|

|

CPES; is being used worldwide in many different climates. From the cold of Finland to the steamy tropics of the South Pacific, customers are protecting and restoring homes, decks, boats, and much more using CPES. Use of Organic Respirator is recommended. |

Clear Penetrating Epoxy Sealer may be used with these products to assist in wood projects:

High Build Epoxy Paint/Primer ™